Tube forming is shaping flat metal into a finished tube form. Tube bending, however, is bending the tube after it has been formed. Tube bending and tube forming are both common metal-forming processes. Read More…

We promise that all of our solutions are safe, accurate, flexible, timely and cost effective. Over the years we have reduced our manufacturing time which has resulted in savings for our customers.

For over 50 years, Haven Manufacturing Corporation has built a solid reputation as the productivity leader in the tube recutting industry. As our business continues to grow, we have kept the focus on providing new cost-effective machinery and total solutions that increase output without adding additional labor resources. You can trust Haven to provide fully integrated solutions to meet all of...

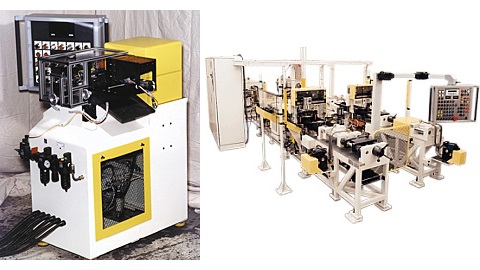

BLM GROUP is a global leader in tube processing, from laser cutting to cold saw, bending, end-forming and measurement. We have a worldwide presence that brings the highest expertise and skill to a wide range of manufacturing sites. Specifically, our line of end-forming machines brings you options for success. Visit our website for details on our TUBE-FORM ELE and our TUBE FORM with a rotary table.

More Tube Forming Equipment Manufacturers

Tube Forming

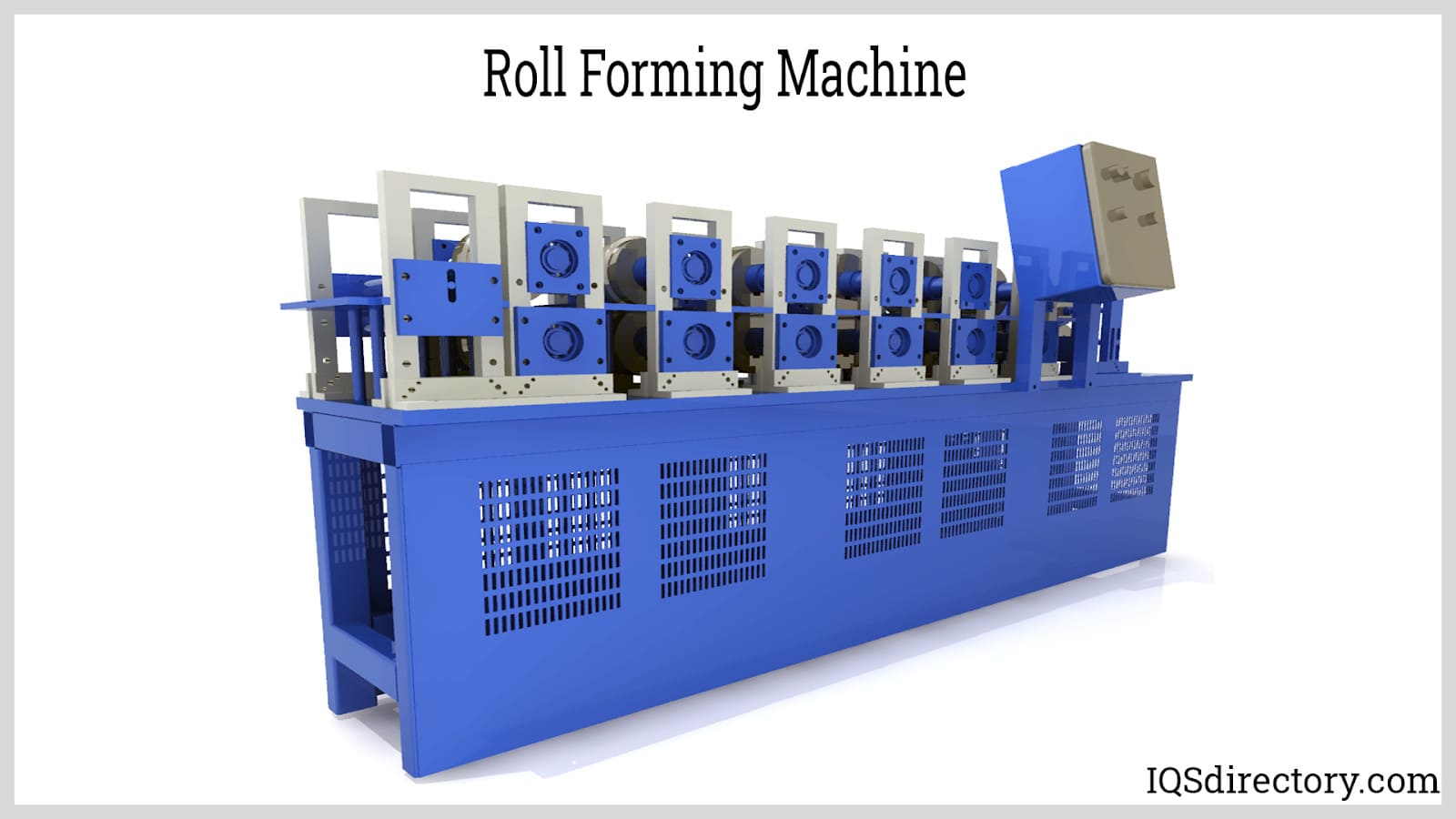

Roll Forming Equipment

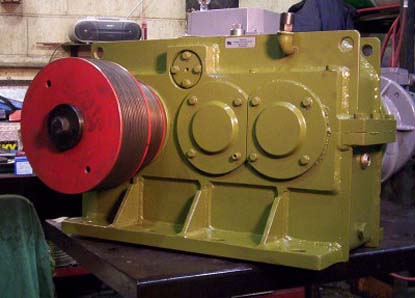

A cold roll-forming machine uses multiple sequentially arranged forming rolls to create special section profiles. The machine horizontally bends metal strips or coils. Cold-formed profiles are increasingly popular because they have polished surfaces and better dimensional accuracy than hot-rolled steel products. Advancements in roll-forming technology have made cold roll-forming machines incredibly efficient and precise.

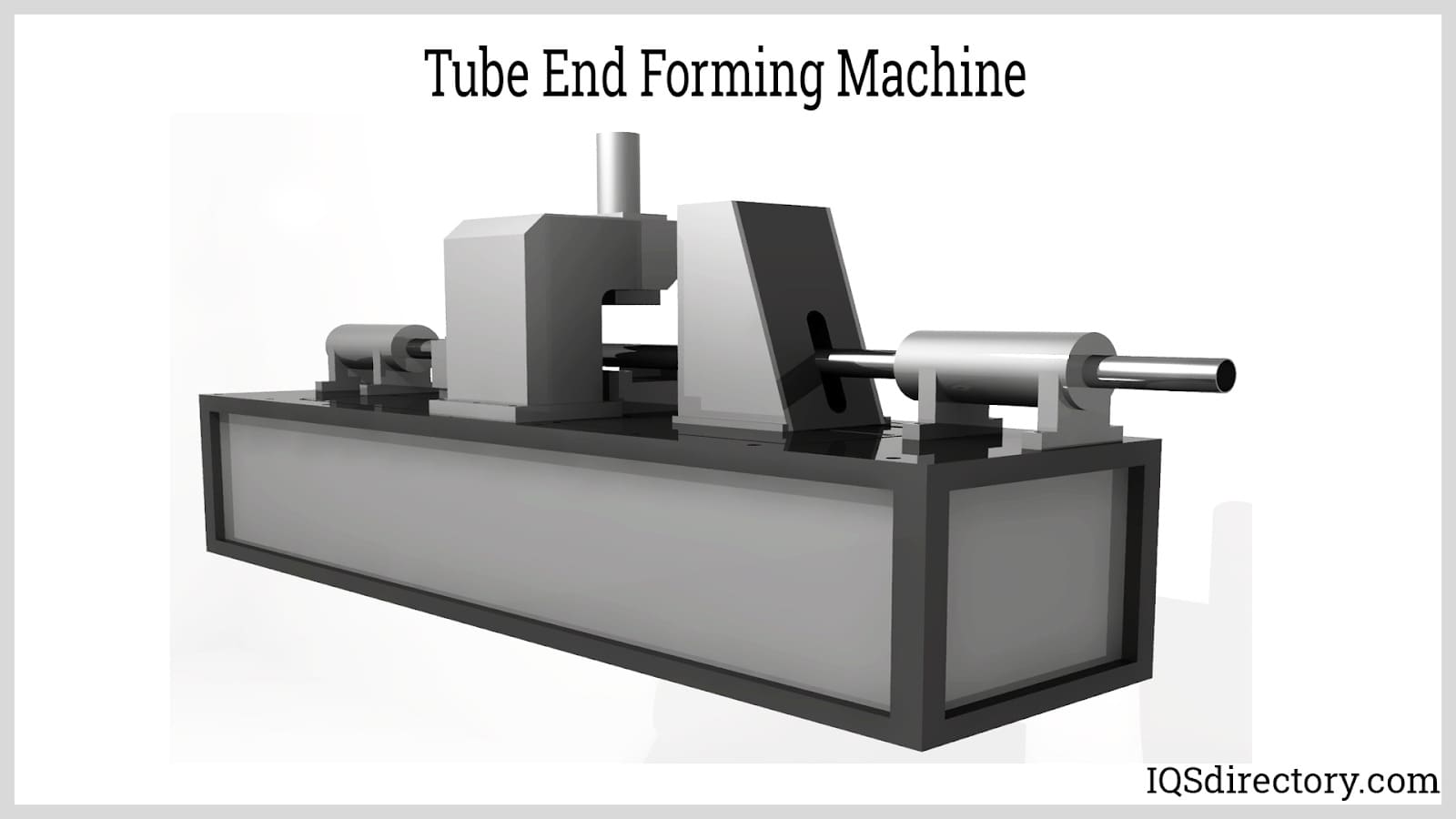

Tube End Forming Processes

Tube end-shaping machinery shapes tube closures based on their applications. Some of these processes are:

- Reduction tube end forming uses dies and tapered rings to shrink a tube’s diameter.

- Expansion tube forming is used to widen tube ends to accommodate different needs. For example, healthcare equipment or heat pump assemblies may require this process.

- Beaded tube end formation can strengthen tubes for specific applications. In this process, beads are added to the end of the tube. Afterward, tubes are easier to connect to hoses or other things.

- Flare tube end forming creates a tight seal at the end of a tube.

Tube Bending

Tube bending is forming metals and other materials into tubing or pipes. Metal tube bending is used for ferrous metals like stainless steel or other steel alloys. Tube bending and forming require a careful design and development process. Some processes may require a tube mill or roll-forming equipment.

Types of Tube Bending

Form-bound tube bending shapes a piece of metal into a die that is custom-made for its intended use. Manufacturers can do form-bound tube bending manually or with technology. Freeform tube bending is not intended to follow the contours of a die. Instead, manufacturers use presses and tube-bending equipment to bend pipes continuously without breaks. This process works best for final parts fashioned from a single continuous piece, like rollover cages. Roll bending illustrates freeform tube bending, in which a pipe or tube is passed between three rollers arranged in a pyramid configuration to shape the tube.

Alternative Bending Methods

Rotary bending: The tubing is drawn into an apparatus and formed using dies and other tools.

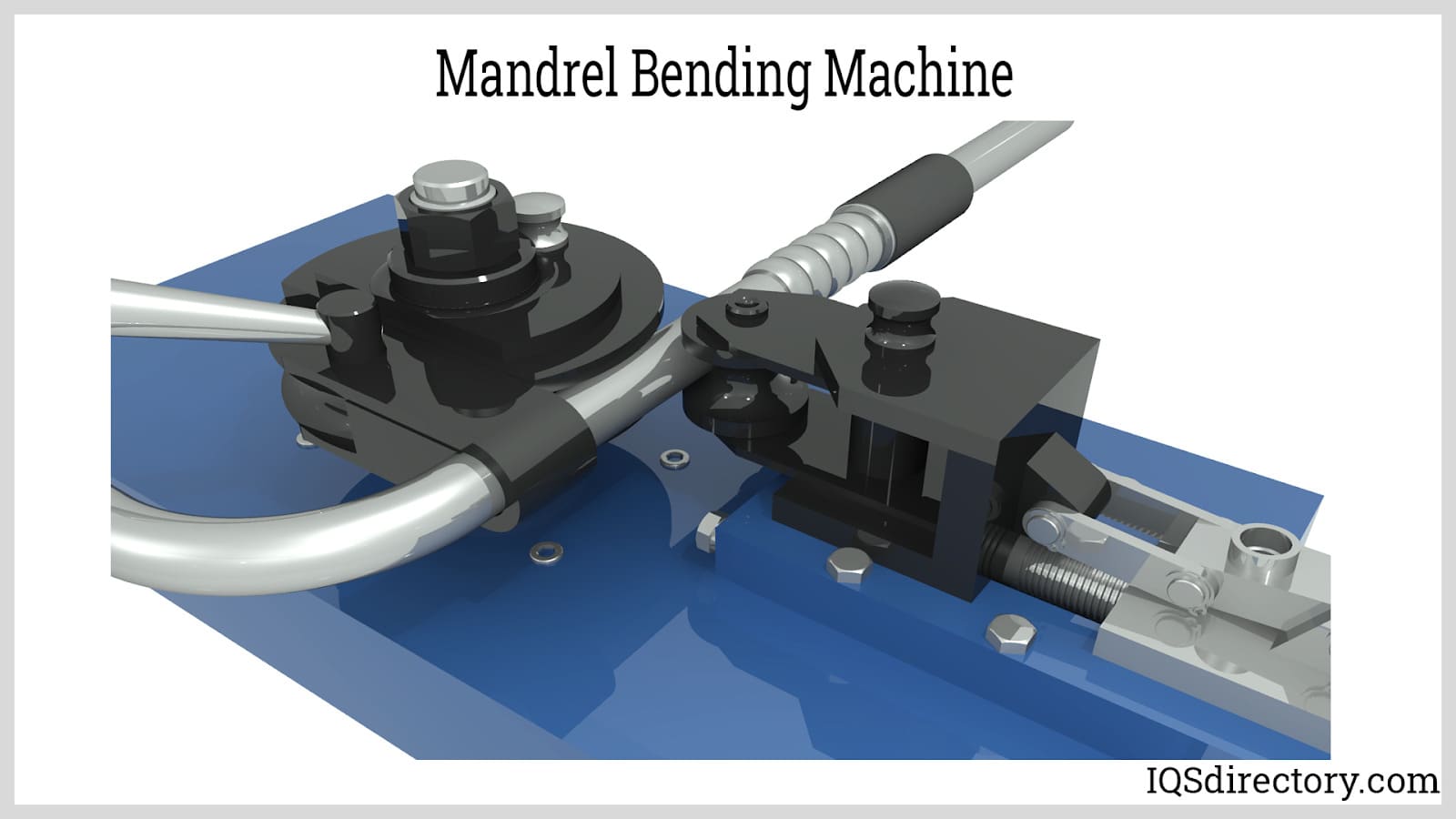

Mandrel bending: A mandrel is a rod that can be inserted into a metal tube and used to shape the tube during the tube-bending process to prevent bend flaws like rippling, flattening, or collapse of the tube. Mandrels are useful when bent material has thinner walls.

Compression bending: In compression bending, a die bends a tube around a secondary, stationary die to complete the final shape.

Roll bending: Roll bending works for large radius bends, where the radius is eight times the material’s thickness. This technique uses dies that can support enormous radiuses or pyramid-shaped rollers.

Choosing the Correct Tube Forming Equipment Manufacturer

To make sure you have the most positive outcome when purchasing tube forming equipment from a tube-forming equipment manufacturer, it is important to compare at least 5 manufacturers using our tube forming equipment directory. Each tube forming equipment manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each tube-forming equipment company website using our patented website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple tube-forming equipment companies with the same message.

Automation Equipment

Automation Equipment Car Wash Equipment

Car Wash Equipment Centrifuges

Centrifuges Hydraulic Presses

Hydraulic Presses Lasers

Lasers Machinery Rebuilders

Machinery Rebuilders Paint Finishing Equipment

Paint Finishing Equipment Tube Forming Machines

Tube Forming Machines Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services