The term “tube forming machinery” refers to any and all equipment that contributes to tube forming. In this case, tube forming does not refer to the formation of tubing, which is called tube fabrication, but rather the process of altering tubing into complex shapes. Note that a tube is a thin, hollow shape used as a passage to convey gas or fluid or as structural components. A tube is typically cylindrical but can be rectangular or square. Also, though they are technically different, in general, you can use the terms tube or pipe interchangeably. Read More…

We promise that all of our solutions are safe, accurate, flexible, timely and cost effective. Over the years we have reduced our manufacturing time which has resulted in savings for our customers.

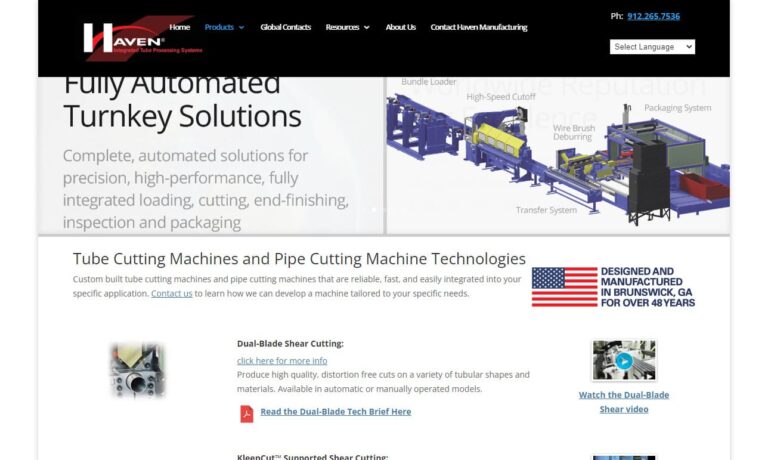

For over 50 years, Haven Manufacturing Corporation has built a solid reputation as the productivity leader in the tube recutting industry. As our business continues to grow, we have kept the focus on providing new cost-effective machinery and total solutions that increase output without adding additional labor resources. You can trust Haven to provide fully integrated solutions to meet all of...

BLM GROUP is a global leader in tube processing, from laser cutting to cold saw, bending, end-forming and measurement. We have a worldwide presence that brings the highest expertise and skill to a wide range of manufacturing sites. Specifically, our line of end-forming machines brings you options for success. Visit our website for details on our TUBE-FORM ELE and our TUBE FORM with a rotary table.

More Tube Forming Machinery Manufacturers

History

Humans have been crafting and forming tubing for millennia. Some of the earliest pipes, dating back to around 2000 B.C. in China, were handmade from reeds. The Romans were also renowned for their aqueduct systems, which transported water throughout Rome and beyond using pipes.

One of the earliest tube fabrication machines was created by James Russell in 1824. Responding to the demand for pipes to fuel London’s coal-burning lamps, he invented a method using a rolling mill. He would heat a flat iron strip until it was malleable, fold and weld it with a drop hammer, and then pass it through a groove and rolling mill. However, in 1825, Comenius Whitehouse developed a process called butt-welding, which rendered Russell’s method obsolete and laid the foundation for modern pipe-making. This process involved heating thin sheets of iron and drawing them through a cone-shaped outlet, which shaped the edges into a tube. The pipe was completed by welding the ends together. The first American plant to use Whitehouse’s process opened in Philadelphia in 1832.

In the 1840s, metalworkers began creating seamless tubes by drilling into solid circular billets, heating them, and drawing them through dies to form pipes. This method, however, produced uneven wall thicknesses and was difficult to drill. To address this, in 1888, a manufacturer developed a technique where a hollow tube was created by casting a solid billet around a fireproof brick core.

By the late 1800s and early 1900s, the manufacturing of automotive parts such as oil and gas lines, as well as bike parts, led to the opening of the first seamless tube manufacturing plant in 1895. The next major innovation in tube fabrication came in the early 1900s with the development of a process for hot forming tube elbows using elbow benders, allowing for quicker and larger-scale production. In 1911, John Moon built machinery for continuous tube forming.

The 1960s saw the invention of the high-frequency induction bending machine, enabling more precise results. This was followed by the development of Computer Numerical Controlled (CNC) technology, which allows manufacturers to design on a computer and have the machine execute the design. CNC machining has greatly increased the speed, ease, and complexity of tube fabrication, allowing for more intricate designs, tighter bends, thinner walls, and higher production volumes.

Following CNC technology, engineers developed other computer-assisted tools, such as CAD (computer-aided design) software. These innovations have made tube forming machinery more efficient and have contributed to the growth of tubing companies like Universal Tube. As technology continues to advance, we can expect even more precise and innovative tube-forming machinery in the future.

How It Works

Common forming services encompass cutting, bending, and joining. Additional processes executed by tube forming machinery include packing, tube flaring, threading, coining, and nitinol heat setting.

Packing

Packing is a bending process where a tube is filled with a material to aid in its formation. Examples include ice packing and sand-packing/hot-slab forming.

Ice Packing: This straightforward method involves filling a tube with a water solution, freezing it, and then bending it. The solution has properties that make the ice flexible. This technique is often used to make trombones.

Sand-Packing/Hot-Slab Forming: This process begins with filling a tube with fine sand. The tube is then capped at both ends and heated in a furnace to at least 1600℉. Once heated, the tube is bent around pins on a slab using mechanical force, such as a crane or a winch. After cooling, the sand is removed, which helps minimize distortion in the tube’s cross-section.

Tube Flaring

Tube flaring aims to form the end of a tube into a funnel shape, or tube flare. This simple process is carried out using tube end forming machines.

Tube Threading

Tube threading involves creating raised helical ribs, or threads, on the end of a tube. This can be done internally or externally, with both types designed to connect to each other, allowing separate pieces of tubing to be joined.

Coining

In tube forming, coining refers to flattening the tubing. This process involves using custom tooling, dies, and power presses to achieve the desired flatness.

Nitinol Heat Setting

Nitinol heat setting is a specialized process applied exclusively to nickel-titanium, a shape-memory alloy composed of equal parts nickel and titanium. During this process, the tubing is forced through a die and baked at high temperatures, repeating the baking several times until the shape is heat-set.

Types

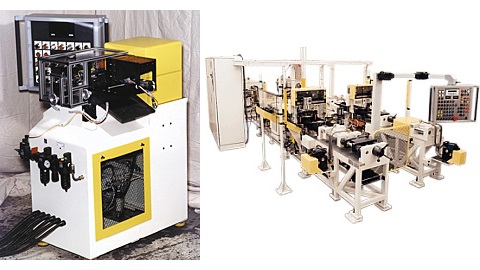

As a general rule, tube forming machinery must maintain high accuracy. Therefore, these machines are typically either automated manufacturing cells or dedicated machines.

Automated manufacturing cells can be programmed for a variety of applications.

Dedicated machines are designed for specific tasks and cannot accommodate design changes.

There are many types of machinery within the categories of automated manufacturing cells and dedicated tube forming machines. Generally, tube forming machinery is quite diverse and includes tube cutting machines, tube end forming machines, bending machines, tube notchers, tube rollers, and tube swaging machines.

Tube cutting machines cut tubing to various lengths and shape the ends. They are highly precise, creating burr-free circular and square ends.

Tube end forming machines also perform cutting tasks, but they are specifically designed to shape the tube end. They can perform chamfering, end expansion, roll beading, end reduction, flanging, flaring, and notching.

Bending machines, also known as tube benders or tube bending equipment, curve and twist tubes. This category includes various types, such as roll benders, rotary draw benders, and mandrel tube benders.

Roll benders change the bend radius of a tube by passing it through a series of pressure-applying rollers.

Pipe benders perform similar functions on pipes and may be called exhaust pipe benders when used in this context.

Tube notchers create notches in tubes by cutting vertically and perpendicularly into the tubing’s surface.

Tube rolling machinery, a type of roll forming equipment, rolls metal strips into various tube diameters.

Tube mill equipment, or tube mills, is almost identical to tube rolling machinery. It produces tubing or piping by continuously rolling a metal strip until the edges meet and are welded.

Tube swaging machines, or swaging machines, are cold metalworking machines that use high pressure or a die to permanently join multiple tubes.

Hydroforming machines shape tubes using fluid pressure, which forces the tube material into a forming die, causing extreme shape deformation. These machines create strong parts with uniform thickness.

Design and Customization

When designing tube forming machinery, manufacturers consider various application factors, such as the complexity of the tube shapes (cuts, bends, flaring, etc.), the length and wall thickness of the tubes, the material (e.g., steel, stainless steel, aluminum for metal tubes; PVC, polycarbonate, ABS for plastic tubes), the daily production volume, the desired level of automation, the need for integration with existing systems, and compliance with standards.

Manufacturers use state-of-the-art equipment to create your machinery. To ensure the machines meet your specific needs, they can customize various system aspects, including the control system, forming capabilities, and functions (such as tube cutting, pipe threading, automatic feeding, and sorting), as well as in-line secondary operations (like coating, painting, and powder finishing).

Choosing a Manufacturer

If you are in the market for tube forming machinery, it’s crucial to partner with an experienced and reliable supplier. To assist you, we’ve compiled a list of trusted manufacturers, which you’ll find detailed in our industry information paragraphs. Before reviewing them, we recommend noting your specific requirements to streamline your search. Consider factors such as the size and shape of the tubes you intend to create, the complexity of the tubes, your daily production volume, any existing systems, industry standard requirements, your budget for machinery and tooling, your delivery deadline, delivery preferences, installation assistance preferences, and post-installation support needs.

Once you have your specifications written down, begin browsing. Select three or four tube forming machine manufacturers that interest you the most. Reach out to each one to discuss your application, ensuring you cover all the points on your specifications list. After speaking with representatives from each company, compare your conversations. Choose the company that offers the best services for your needs and inform them of your decision to work with them.

Automation Equipment

Automation Equipment Car Wash Equipment

Car Wash Equipment Centrifuges

Centrifuges Hydraulic Presses

Hydraulic Presses Lasers

Lasers Machinery Rebuilders

Machinery Rebuilders Paint Finishing Equipment

Paint Finishing Equipment Tube Forming Machines

Tube Forming Machines Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services