Tubing is an important resource that is used by several industries as a means for installing electrical wiring and supplying water and gas. There are a wide variety of tubing sizes and shapes that are used in construction and manufacturing. Read More…

We promise that all of our solutions are safe, accurate, flexible, timely and cost effective. Over the years we have reduced our manufacturing time which has resulted in savings for our customers.

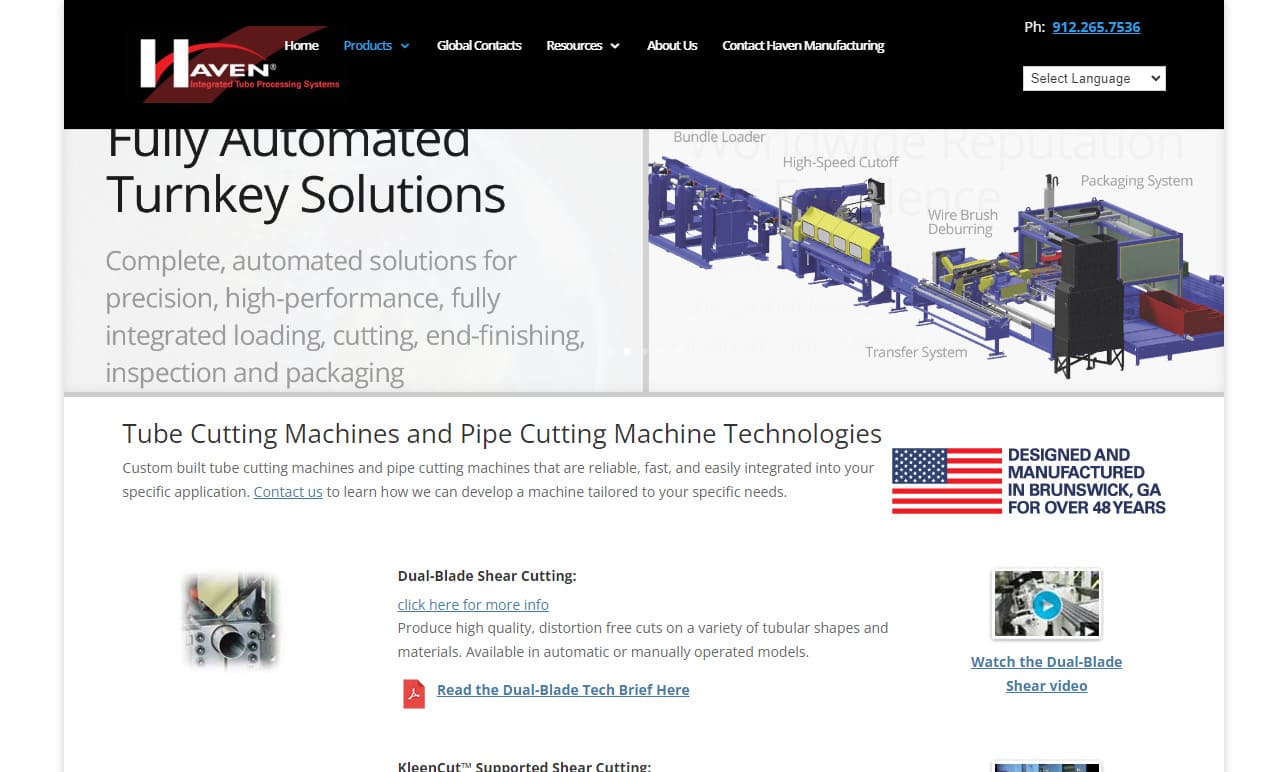

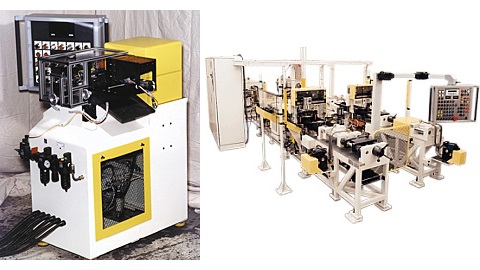

For over 50 years, Haven Manufacturing Corporation has built a solid reputation as the productivity leader in the tube recutting industry. As our business continues to grow, we have kept the focus on providing new cost-effective machinery and total solutions that increase output without adding additional labor resources. You can trust Haven to provide fully integrated solutions to meet all of...

BLM GROUP is a global leader in tube processing, from laser cutting to cold saw, bending, end-forming and measurement. We have a worldwide presence that brings the highest expertise and skill to a wide range of manufacturing sites. Specifically, our line of end-forming machines brings you options for success. Visit our website for details on our TUBE-FORM ELE and our TUBE FORM with a rotary table.

More Tube Fabricating Machinery Manufacturers

Each type is designed and fabricated to fit precisely into an application. In many ways, tubing is one of those essential tools that tends to be over looked.

When envisioning tubing, most of us think of long lengths of tubes piled and ready for use. For tubing to reach its full potential, it has to be changed and shaped by tube fabricating machinery.

What is Tube Fabricating Machinery?

Though long lengths of tubing are strong and useful, they need to be shaped and formed to meet the needs of the final product. The necessary steps used to perform the final parts of tube production are completed by tube fabricating machinery, which are well-designed and engineered pieces of equipment capable of performing a variety of tubing shaping functions.

There are several forms and types of tube fabricating machinery with some capable of performing multiple functions while others are able to complete just one. The main purpose of tube fabricating machinery is to put the final touch on tubing by bending, flanging, swaging, and reducing it.

Much like any other form of production equipment, some forms of tube forming machinery use computer numerical control (CNC) programming to perform some of their operations. CNC machines are capable of completing several tube fabricating functions in a single step.

Tube Fabricating Machinery Processes

There are many varieties of tube fabricating processes each of which is designed to transform the raw material tubing into a useful shape. Much of what is completed in tube form is designed to replace the need for joints and tubing connectors. In the case of bending, fabricating machines bend the tubing such that it can go around a corner avoiding the need for an elbow joint.

The processes of tube fabricating machinery are performed such that tubing can be used by its full length without needing to be cut or joined. This is especially beneficial in sections of a structure that has limited access. Tubes that have been formed to comply with the design of the building without the use of connectors prevents any concern for leaks or cracks in the tubing.

The Benefits of Tube Fabricating Machinery

Machines used for tube forming and shaping are a cost and labor-saving method for the creation of tubing that is easy to install as well as safe and worry free. It is a method of tubing production that produces tight and secure products using exceptional precision and accuracy.

Automation Equipment

Automation Equipment Car Wash Equipment

Car Wash Equipment Centrifuges

Centrifuges Hydraulic Presses

Hydraulic Presses Lasers

Lasers Machinery Rebuilders

Machinery Rebuilders Paint Finishing Equipment

Paint Finishing Equipment Tube Forming Machines

Tube Forming Machines Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services