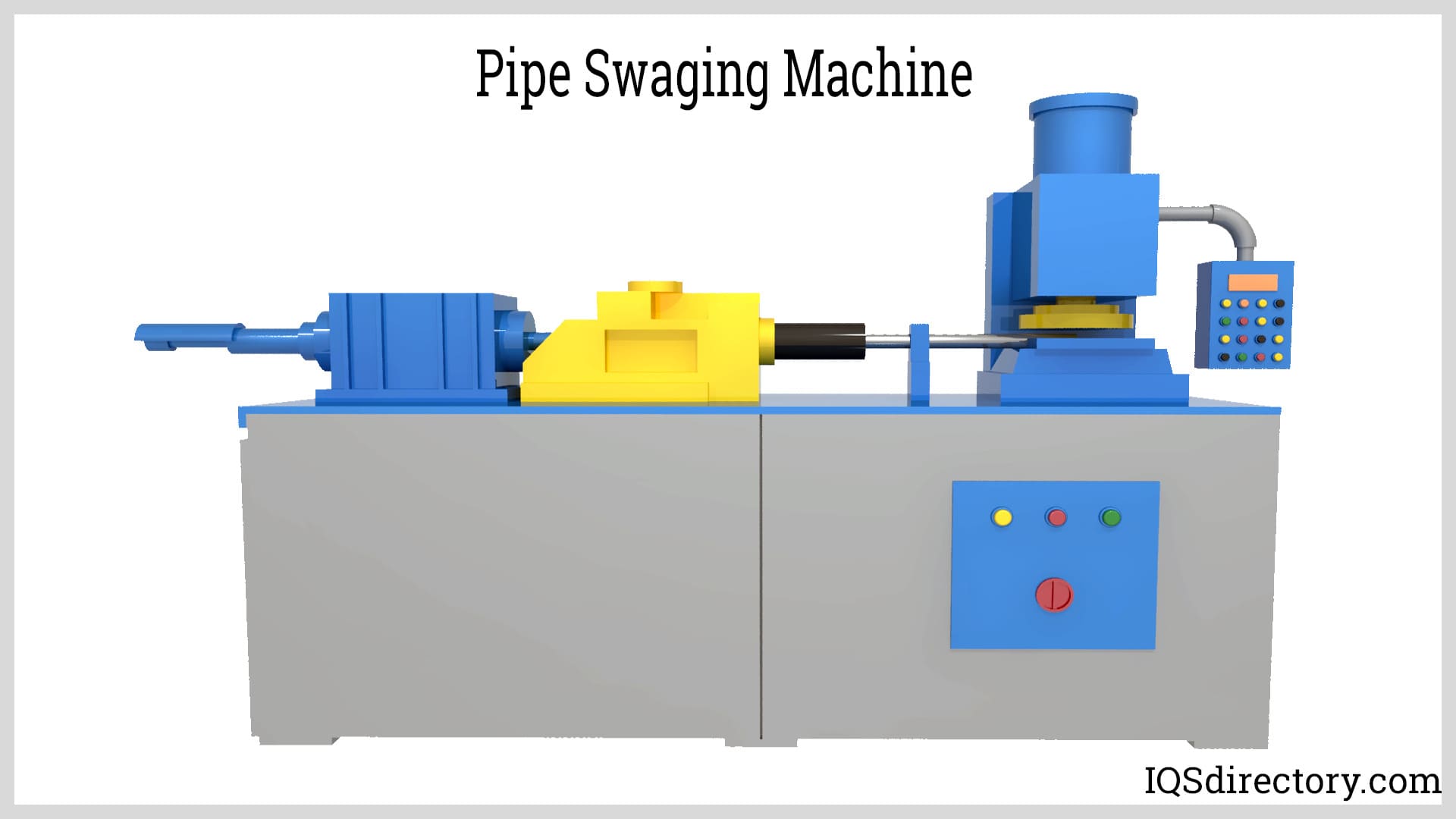

Swaging is fundamentally a metal shaping technique that reduces rod, wire, or tube. Tube swaging is the process of fitting tubes together by changing the tube’s diameter at the pipe’s end. Long lengths of cable, rod, or tube are fed through the water while reducing or swaging. As a result, the material is shortened from end to end during the process, resulting in a lower overall diameter and the desired tensile strength. A series of hammer blows are used to shape the object instead of other techniques. This process of chip–less metal shaping is effective for producing goods with little material waste. It is a cost–effective way for redrawing metal wire, rod, and tubing. Read More…

We promise that all of our solutions are safe, accurate, flexible, timely and cost effective. Over the years we have reduced our manufacturing time which has resulted in savings for our customers.

For over 50 years, Haven Manufacturing Corporation has built a solid reputation as the productivity leader in the tube recutting industry. As our business continues to grow, we have kept the focus on providing new cost-effective machinery and total solutions that increase output without adding additional labor resources. You can trust Haven to provide fully integrated solutions to meet all of...

BLM GROUP is a global leader in tube processing, from laser cutting to cold saw, bending, end-forming and measurement. We have a worldwide presence that brings the highest expertise and skill to a wide range of manufacturing sites. Specifically, our line of end-forming machines brings you options for success. Visit our website for details on our TUBE-FORM ELE and our TUBE FORM with a rotary table.

More Tube Swaging Machine Manufacturers

Metal pieces can also be sized, reduced, shaped, tapered, bonded, or formed using this process. Tube ends can be flanged, flared, slotted, notched, flattened, or punched. Several types of tube swaging machines are rotary swaggers, long die swaggers, and pipe flaring devices. Metal tubes composed of several metals, such as steel, aluminum, brass, copper, titanium, and stainless steel, are swaged using machinery.

Tube Swaging Processes

- Assembling– A fitting is first put over the cable when constructing components like recreational ropes course cables and sailing rigging equipment. Then, it is put into the water, where a component is assembled thanks to the cold–force action of the hammers.

- End Forming– A single piece of tubing is placed into the water to a predetermined depth before being shrunk to the needed diameter. The component can perform subsequent operations like drilling, drawing, or tapping. This method is used to create fluid control tubes and aeronautical tube components.

Types of Tube Swaging Machines

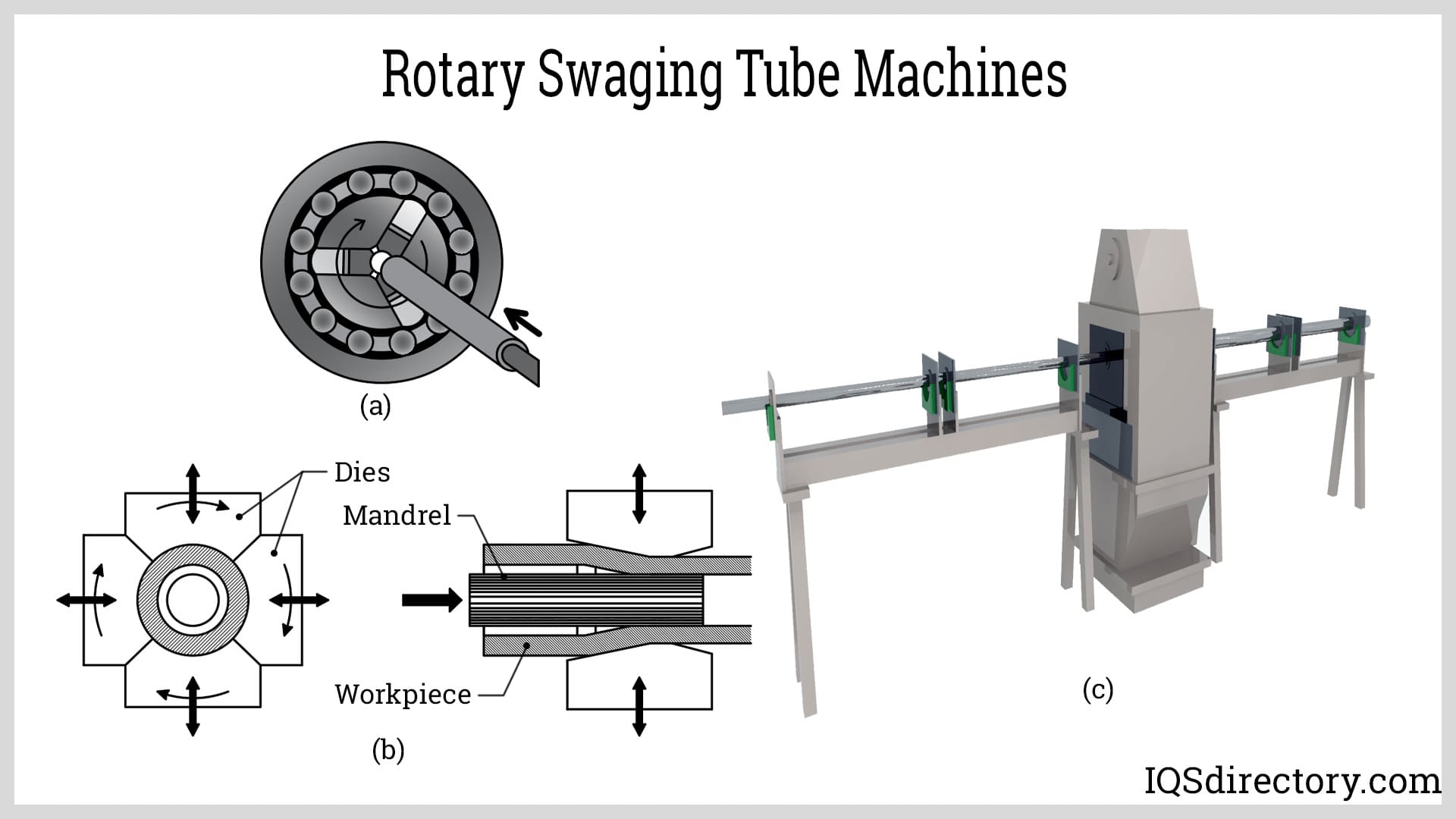

Three fundamental forms of swaging can be performed using swaging machines.

- Rotary Swagers– A rotary swager is the best option for design elements for symmetrical pieces. It produces items of superior quality because of the same rotation of its hammers and dies around the product. Some suppliers provide nine standard swager sizes with capacities ranging from 1/16" to 3–3/8" for solid and 1/4" to 6" for tubing.

- Stationary Die Swagers– For cross sections other than circular. It is possible to forge asymmetrical shapes in a stationary die swager since the dies and hammers do not revolve. Manufacturers provide two types: the patented alternate blow (fluted forms, cross circular sections) and simultaneous blow (rectangular shapes, squares, and hexagons).

- Long Die Swagers– Long die swagers from reliable manufacturers create taper tubing up to 24" long, ideal for long and shallow designs. Long die swagers can be utilized with a wide range of nonferrous and ferrous materials. This technique can produce things for the aerospace, sporting goods, and home furnishings industries.

Benefits of Tube Swaging

Swaging is a metal–forming type with a lot to offer businesses. Benefits of swaging machines include:

- High Finish– Because the finished product has a high finish, secondary processes may not be necessary, saving time and money.

- Speedy Assembly– Fittings can be connected to various additional parts, such as wire cable, tubing, hose, flexible tubing, and rod. Additionally, tubes are simple to crimp together.

- Less Material is Used– Instead of being wastefully chipped away, the material is longitudinally moved as it is hammered.

- Reduced Labor Costs– Labor costs are reduced because highly skilled operators are not required. A single operator can manage many machines that incorporate feeds and material–handling devices.

- Low–Cost & Flexible Tooling– Swagers' tooling is incredibly adaptable, and die changes are simple and rapid.

- Reduced Need for Inventory– Fewer components must be maintained on hand since swaging can be done to the required sizes and finishes.

- Swaging gives more control over wall thickness throughout the process, thanks to using a mandrel.

Applications for Tube Swaging Machines

The aerospace, automotive, renewable energy, medical, and military are among the industries that employ the tubes that swaging machines produce. We examine these applications of tube swaging below.

- Military– Swaging is utilized in the military sector to create components like rifle barrels and anti–tank rocket tips. Additionally, MS–spec fittings are swaged into a cable.

- Automotive– Swaging machines manufacture various car parts, such as assemblies for emergency brake cables, steering parts, and drive shafts.

- Medical– Among the many medical products that are swaged are hypodermic needles, catheter band assemblies, and optical equipment.

- Renewable Energy– Swaging machines may be used to expertly produce cartridge heaters, superconducting material, and zirconium rods, components upon which the renewable energy industry depends.

- Aircraft– Swaging ensures the aerospace industry receives control rods, wire rope cable assemblies, and fluid transfer tubing of the highest caliber.

Choosing the Proper Tube Swaging Machine Company

To make sure you have the most productive outcome when purchasing a tube swaging machine from a tube swaging machine company, it is important to compare at least 4 companies using our tube swaging machine directory. Each tube swaging machine company has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the company for more information or request a quote. Review each tube swaging machine company website using our proprietary website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple tube swaging machine companies with the same message.

Automation Equipment

Automation Equipment Car Wash Equipment

Car Wash Equipment Centrifuges

Centrifuges Hydraulic Presses

Hydraulic Presses Lasers

Lasers Machinery Rebuilders

Machinery Rebuilders Paint Finishing Equipment

Paint Finishing Equipment Tube Forming Machines

Tube Forming Machines Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services