End forming is a way to expand or shrink the diameter of a tube’s end. Many manufacturers use tube end forming for cost-effectiveness. Read More…

We promise that all of our solutions are safe, accurate, flexible, timely and cost effective. Over the years we have reduced our manufacturing time which has resulted in savings for our customers.

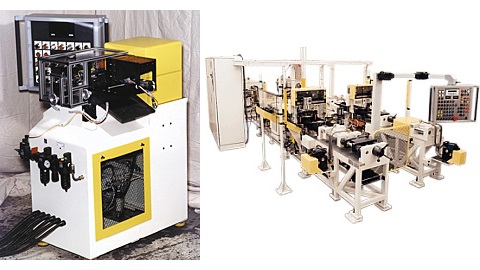

For over 50 years, Haven Manufacturing Corporation has built a solid reputation as the productivity leader in the tube recutting industry. As our business continues to grow, we have kept the focus on providing new cost-effective machinery and total solutions that increase output without adding additional labor resources. You can trust Haven to provide fully integrated solutions to meet all of...

BLM GROUP is a global leader in tube processing, from laser cutting to cold saw, bending, end-forming and measurement. We have a worldwide presence that brings the highest expertise and skill to a wide range of manufacturing sites. Specifically, our line of end-forming machines brings you options for success. Visit our website for details on our TUBE-FORM ELE and our TUBE FORM with a rotary table.

More Tube End Forming Machine Manufacturers

Tube end-forming machines can create multiple end forms for different uses. Manufacturers reshape tube ends to connect the tubes to different media. Tube ends can undergo reduction, expansion, beading, flaring, and thickening. These options have specific requirements to be useful for different purposes.

Tube End-Forming Options

- Expanded ends: Expansion widens the tube end's exterior diameter. Expansion is used to make one tube end fit inside another. For example, healthcare equipment and heat pump assemblies both contain expansion endings.

- Reduced ends: A tube end is reduced when pressed beneath a solid die. Manufacturers also use segmented fingers to shrink tube diameters. Reduction also helps tubes fit within each other.

- Flanged ends: Tubes with flanged ends are often molded to other materials in an assembly process, like glass-to-metal sealing.

- Flared ends: A flared tube end can create a good leak-proof connection. Flared tubes are used to transport liquids in plumbing or other applications.

Ram End Forming Machines

Ram end forming machines are common. The tube is placed into a set of clamp dies shaped to accommodate the specific tube. The dies hold the tube in place while a collection of tools will work on the metal to form the tube's end.

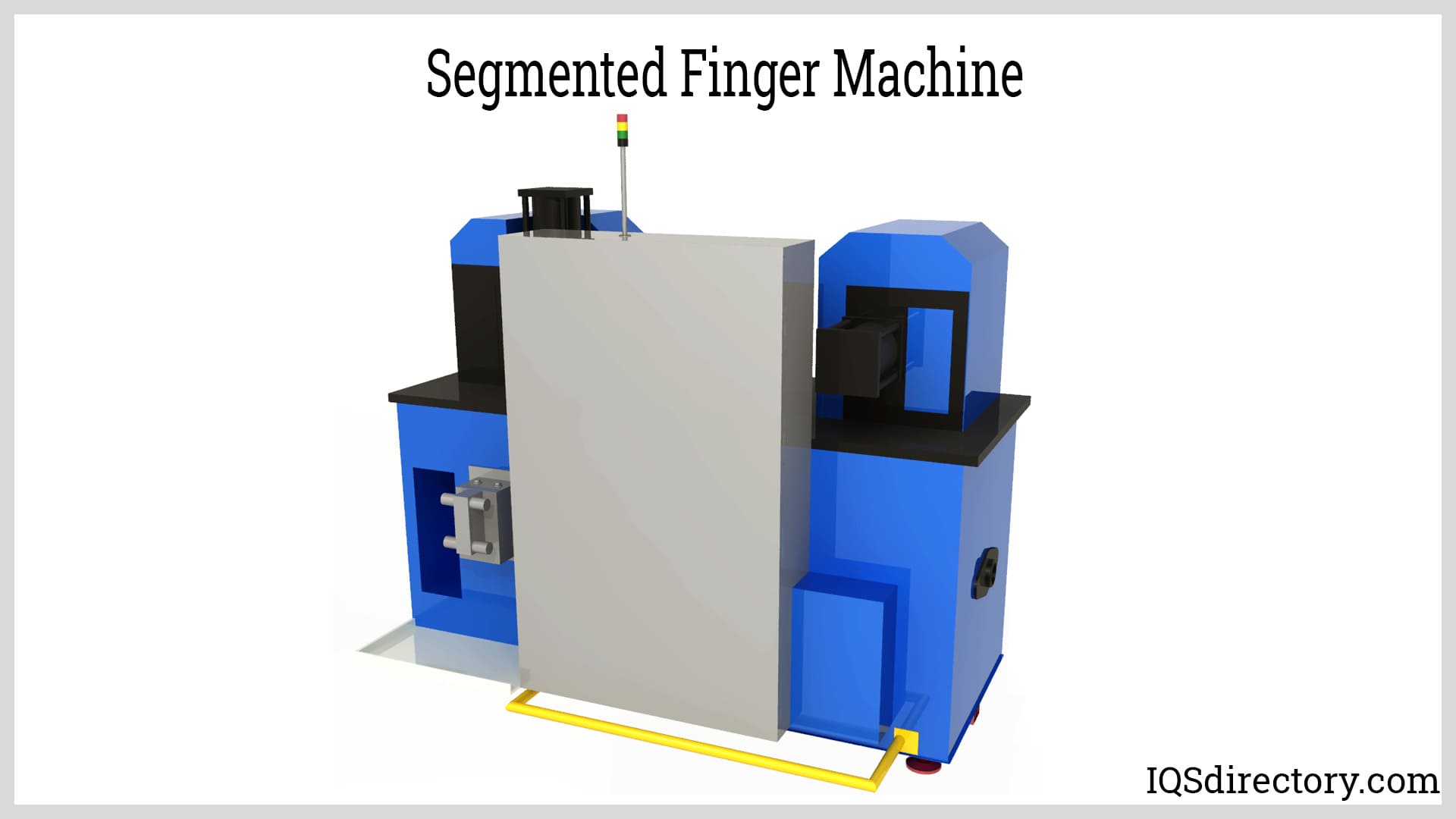

Segmented Tube End Forming Machine

Segmented tube end forming allows for complex tube shaping. Tubes can be resized, reduced, beaded, rounded, and more. Segmented tube end shaping varies widely. There are three kinds of Segmented tube end-forming equipment used throughout the industry.

- Inner and Outer diameter sizers

- Inside/Outside sizers

- Indexing segmented machines

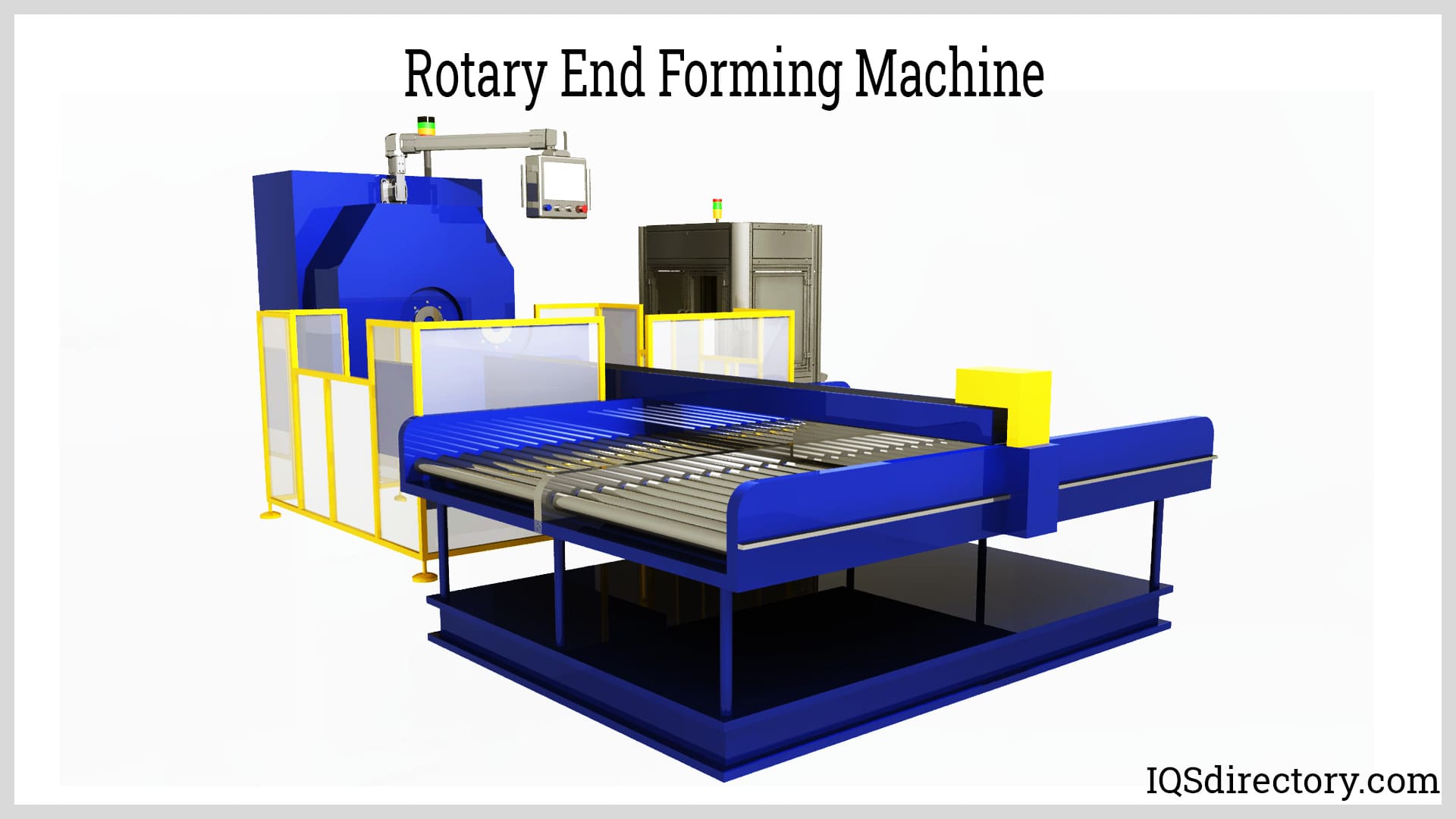

Rotary End Tube Forming Machine

Rotary tube end forming can happen from inside or outside a tube. The tube is held by clamp jaws and then slides over the tool. The tool spins inside the tube during the formation process. This technique works well for grooving or inverted beads.

Choosing the Right Tube End Forming Machine Supplier

To make sure you have the most productive outcome when purchasing tube end-forming machines from a tube end-forming machine supplier, it is important to compare at least 4 to 5 companies using our list of tube end-forming machine suppliers. Each tube end-forming machine supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the supplier for more information or request a quote. Review each tube end-forming machine business website using our proprietary website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple tube end-forming machine businesses with the same form.

Automation Equipment

Automation Equipment Car Wash Equipment

Car Wash Equipment Centrifuges

Centrifuges Hydraulic Presses

Hydraulic Presses Lasers

Lasers Machinery Rebuilders

Machinery Rebuilders Paint Finishing Equipment

Paint Finishing Equipment Tube Forming Machines

Tube Forming Machines Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services