Tube benders refer to many types of electromechanical tube bending equipment. Modern tube benders help optimize manufacturing processes by minimizing production errors. A tube bending machine can handle challenging materials that are up to 1.5 times the outer diameter, have thin walls, have tight radii, or both. The tube’s cross-section is mainly preserved during the bending operation because of the bending mandrel and the counter bearing. Read More…

We promise that all of our solutions are safe, accurate, flexible, timely and cost effective. Over the years we have reduced our manufacturing time which has resulted in savings for our customers.

For over 50 years, Haven Manufacturing Corporation has built a solid reputation as the productivity leader in the tube recutting industry. As our business continues to grow, we have kept the focus on providing new cost-effective machinery and total solutions that increase output without adding additional labor resources. You can trust Haven to provide fully integrated solutions to meet all of...

BLM GROUP is a global leader in tube processing, from laser cutting to cold saw, bending, end-forming and measurement. We have a worldwide presence that brings the highest expertise and skill to a wide range of manufacturing sites. Specifically, our line of end-forming machines brings you options for success. Visit our website for details on our TUBE-FORM ELE and our TUBE FORM with a rotary table.

More Tube Bending Equipment Manufacturers

Types of Tube Bending Equipment

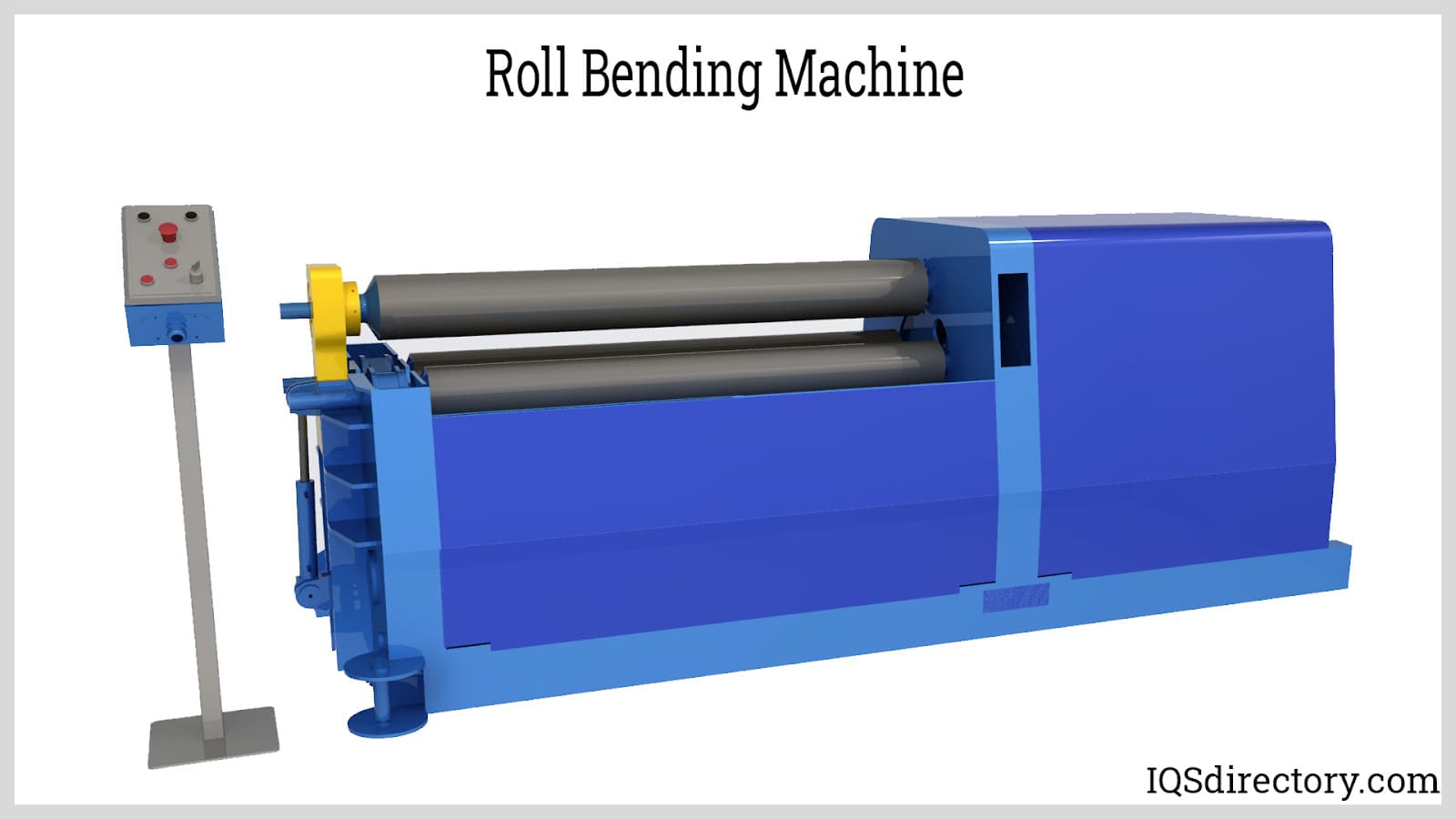

Roll Bending Machine

The 3-roll bender is another name for a pipe-bending device. They are used to produce huge radius bends, like sheet metal roll benders. The positions of the two lower rollers are set, but the height of the upper roller is movable. The tube gradually bends as it moves back and forth between the rollers until the desired outcome is achieved. Tube roll bending obtains excellent results, which results in negligible cross-sectional distortion.

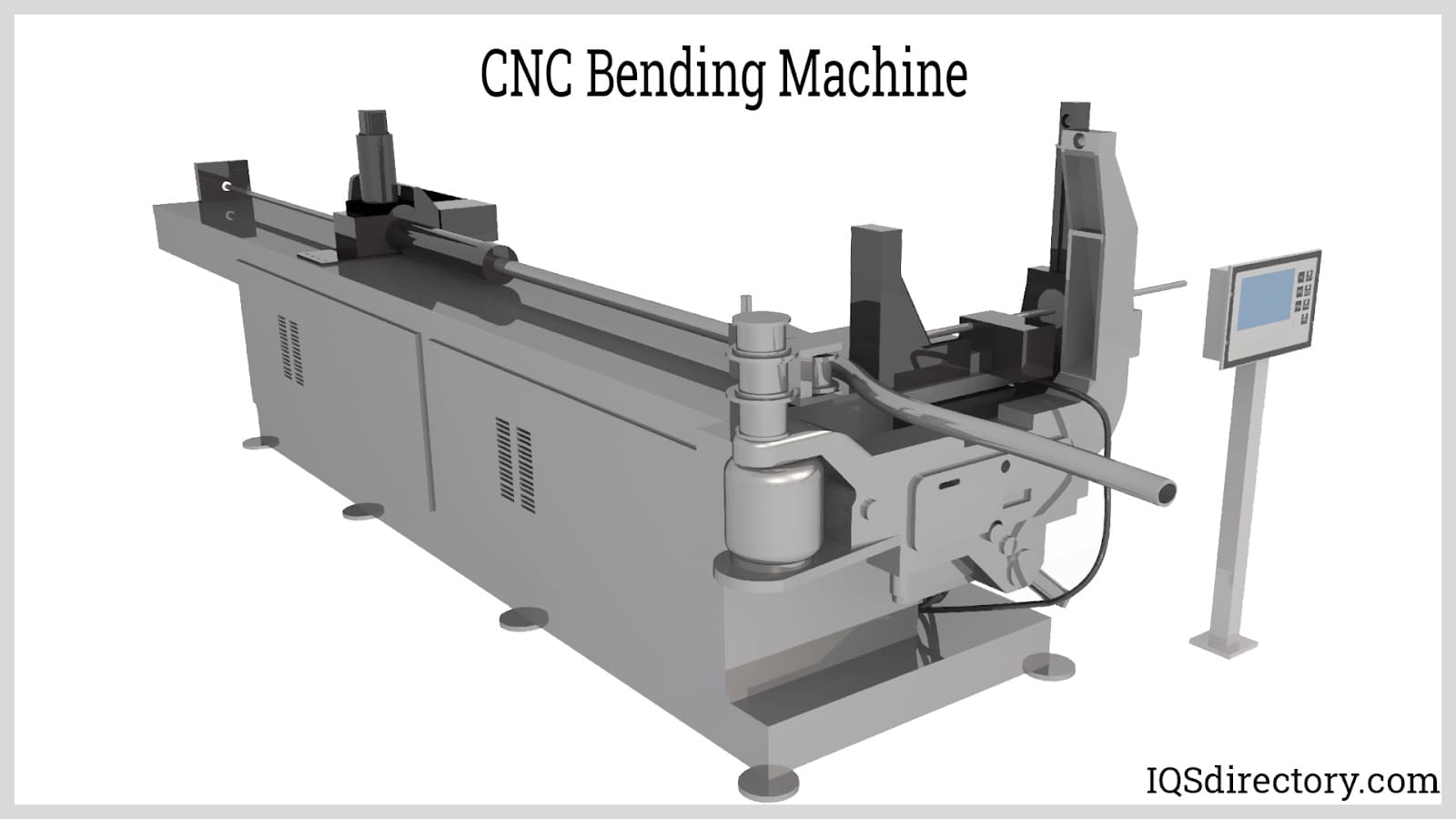

CNC Bending

Most bending today requires human supervision but no manual operation. CNC bending machines help automate actions. Presses and rollers are used with CNC tube bending machines to move the tubes and pipes through the operation. CNC bending is an automated process that increases productivity and efficiency.

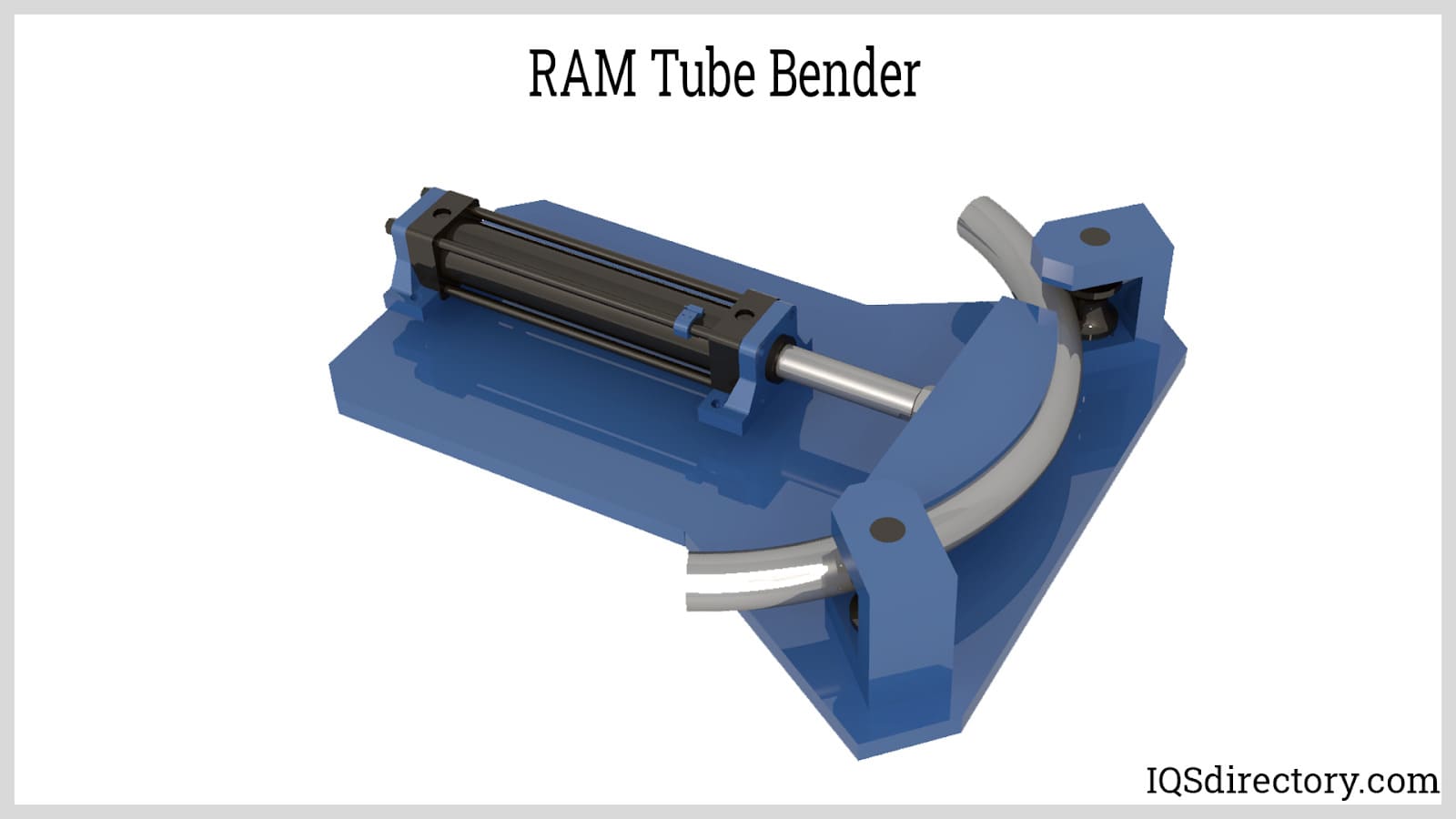

RAM Bending

A RAM bender is also referred to as a press bender, likely the most basic pipe bender available. The stationary dies are first set up on the work surface. The bending angle and bend length are controlled by the space between the dies. The ram's radius affects the bending radius. The ram pushes up against the pipe once everything is in position. The ram successfully forms metal since the dies support the tube's outer wall. Ram bending is only appropriate if cross-sectional distortion is not a problem. A pipe's end has an oval cross-section since there is no internal support for it. RAM bending is useful for straightforward bends where precision and a constant cross section are not priorities.

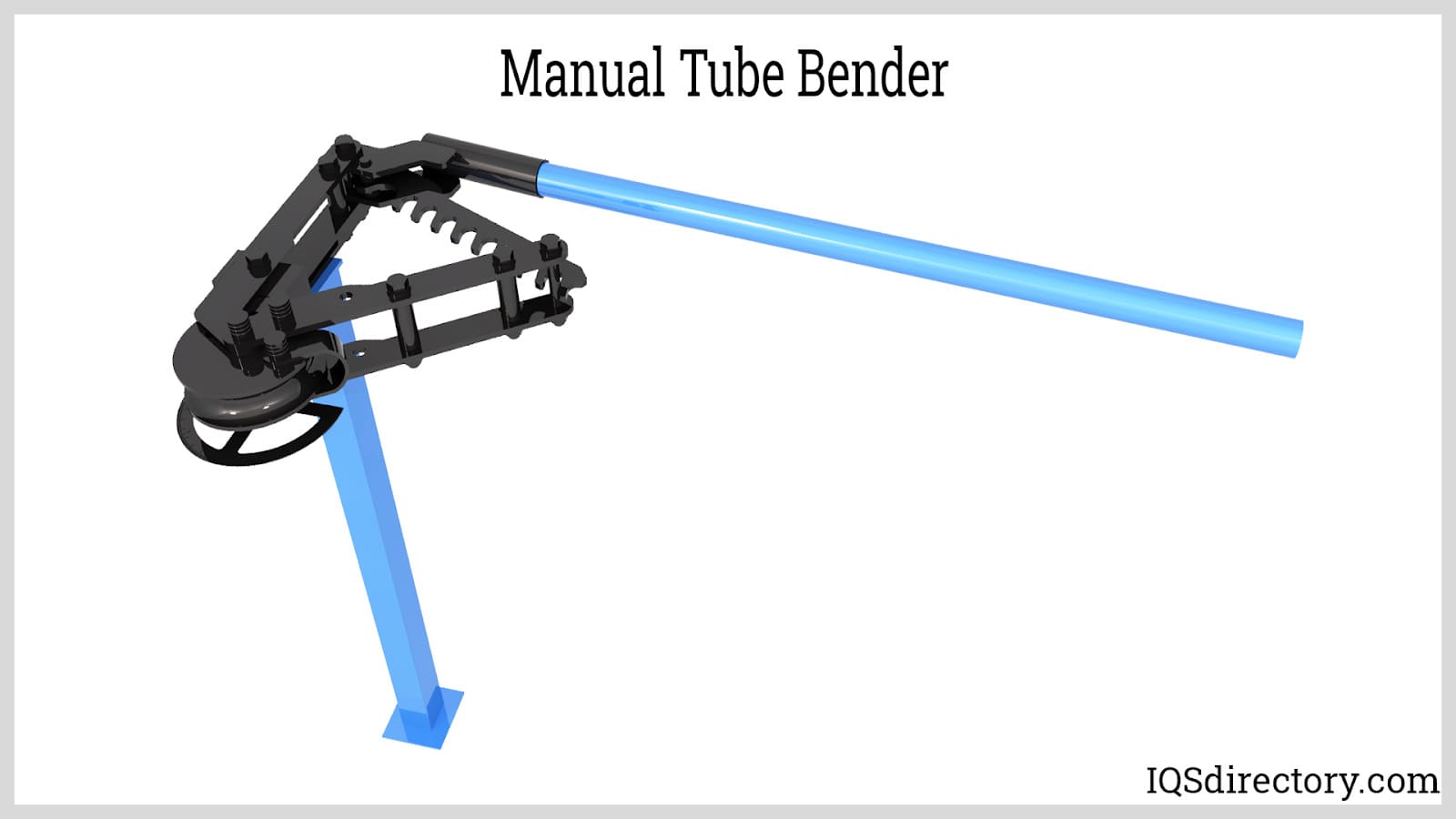

Manual Tube Benders

Users most frequently utilize manual tube benders, also known as hand tube benders, to complete large operations quickly and cheaply. These devices can bend tubes for roll cages, frames, furniture, and more. Manual benders are capable of 180-degree bends, and may be converted to hydraulic benders.

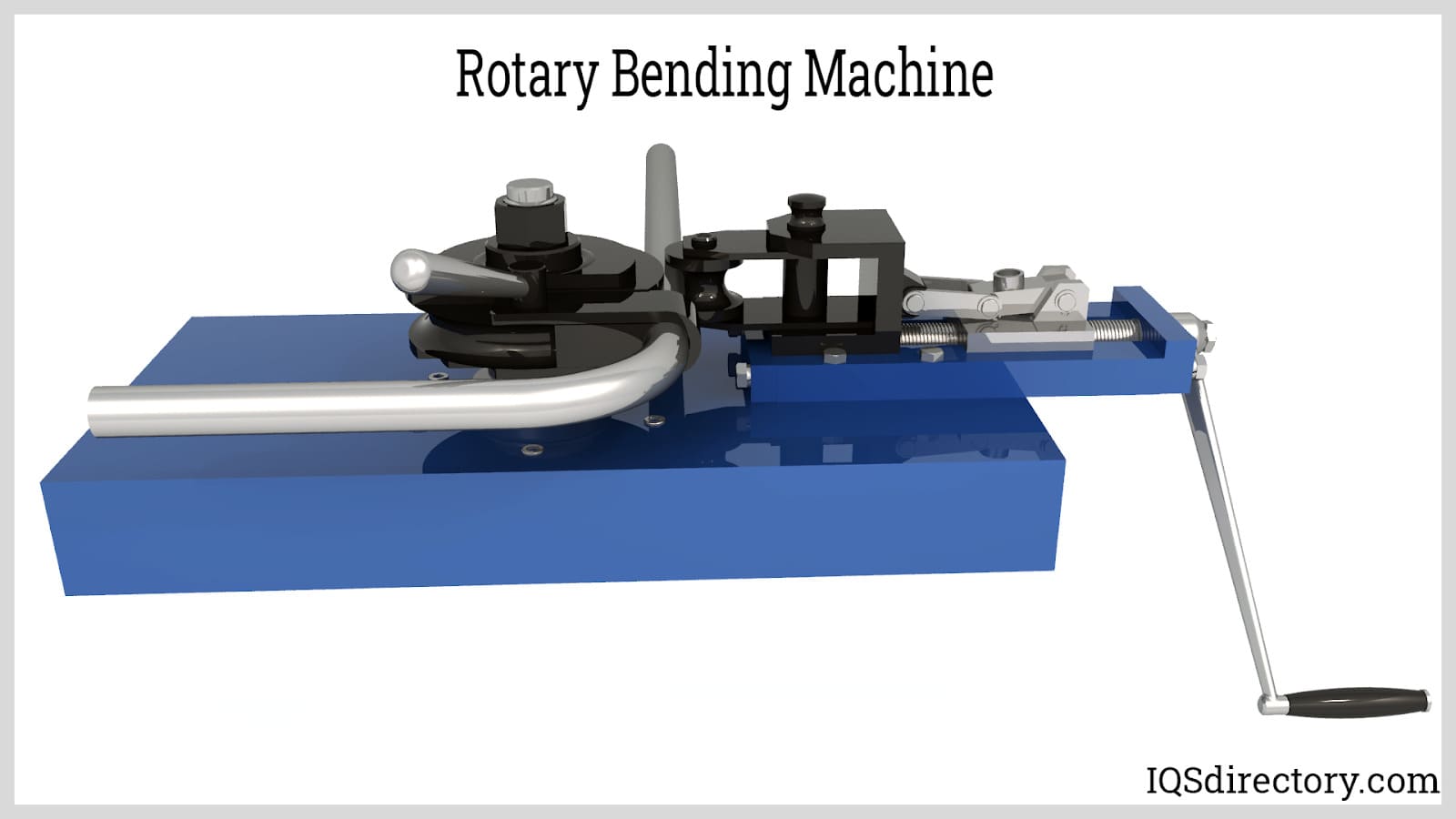

Rotary Bending Machine

A Rotary bending machine is the most common kind of tube bender. The operator uses a clamp die to secure the tube or pipe on the machine. The bend die starts to revolve around its axis. The stationary pressure die ensures that the tube follows the bend die's radius. Manufacturers can add a mandrel and a wiper die for better results. However, this is only necessary for more challenging jobs where deformations are prohibited. A tube with a large diameter and a thin wall thickness, for instance, requires additional support. Rotary benders are accurate and programmable, allowing manufacturers to accomplish entire batches of complex parts.

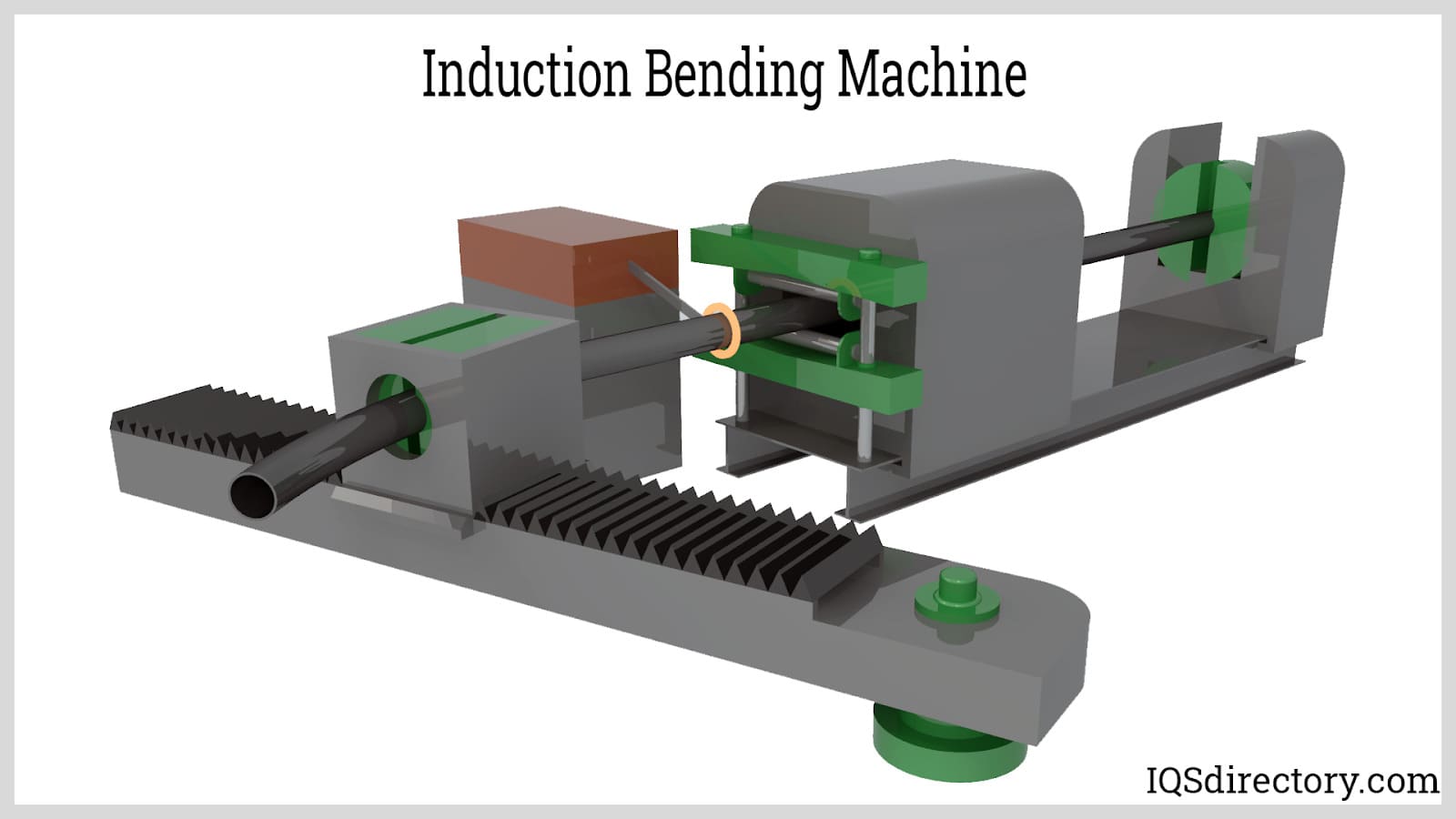

Induction Bending Machines

Induction bending involves drawing a profile via a die. An induction coil is located at the bend to warm the metal. Applying pressure to a heated object means the machine can save energy while bending. Induction bending equipment can bend a wide range of pipe sizes can be bent at a variety of angles. These machines help fashion industrial structural components, bends with small radii, components for heating systems, thick-walled components, etc.

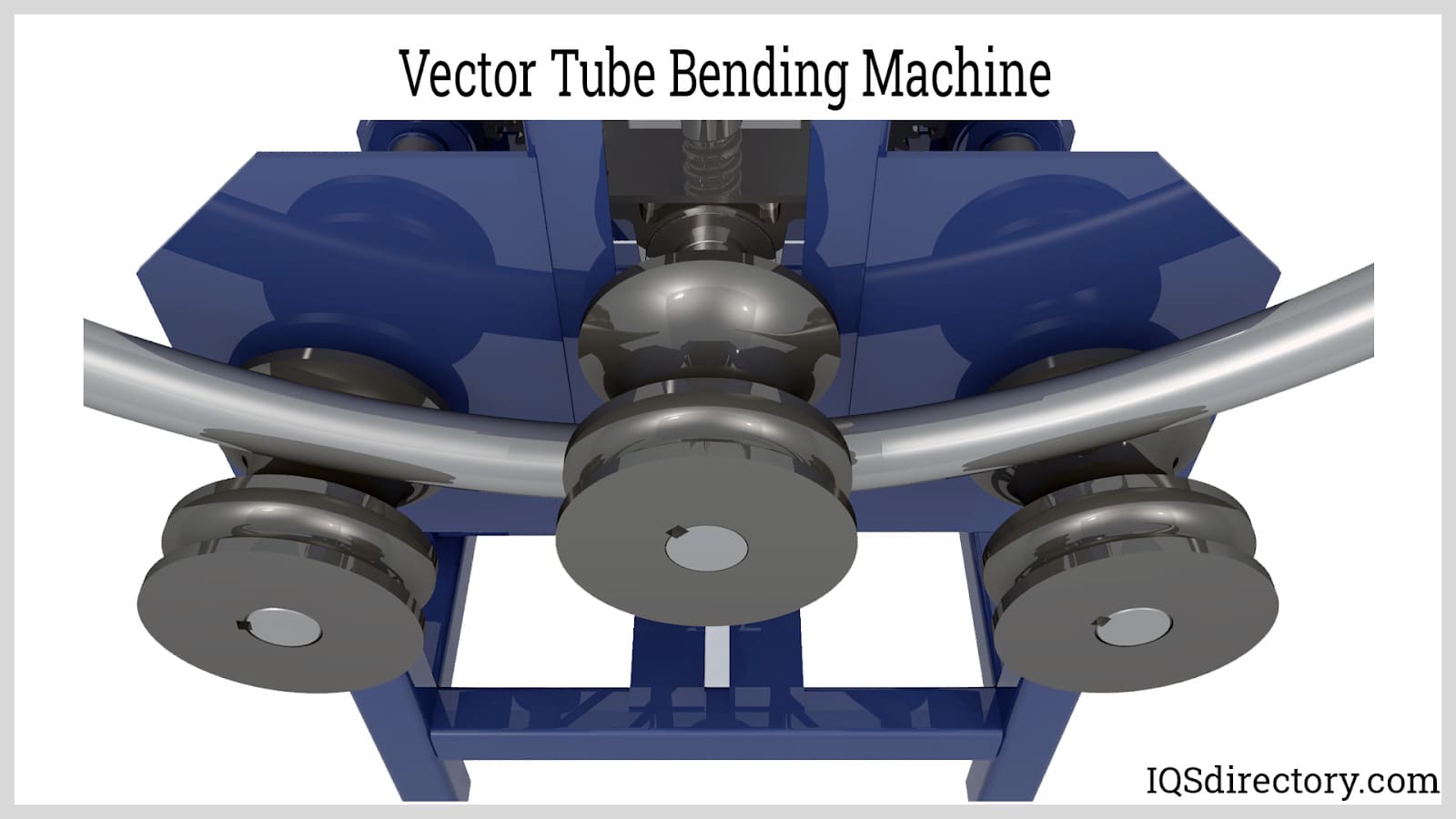

Vector Tube Bending

Vector tube benders accomplish outstanding results. It is extremely accurate because a pipe forms around a rotational draw. The automatic feeding system allows vector tube benders to shape strong materials efficiently. It is often used for automobile and aerospace industries.

Orbital Head Bending Machine

Orbital head-bending machines spin heads and collets around the tubes and are automated or computer-controlled. As a result, they are incredibly productive machines. There are options for automated feeding and offloading. Orbital head bending machines make intricate parts for automobile and air conditioning industries.

Choosing the Proper Tube Bending Equipment Manufacturer

To make sure you have the most beneficial outcome when purchasing tube bending equipment from a tube bending equipment manufacturer, it is important to compare at least 4 manufacturers using our tube bending equipment directory. Each tube bending equipment manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each tube bending equipment company website using our patented website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple tube bending equipment companies with the same quote.

Automation Equipment

Automation Equipment Car Wash Equipment

Car Wash Equipment Centrifuges

Centrifuges Hydraulic Presses

Hydraulic Presses Lasers

Lasers Machinery Rebuilders

Machinery Rebuilders Paint Finishing Equipment

Paint Finishing Equipment Tube Forming Machines

Tube Forming Machines Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services